perlite expansion furnace

Perlite ore is an amorphous volcanic glass, typically formed by the perlite, obsidian, pitchstone. It can be greatly expanding when heated sufficiently.

Expanded perlite is produced by perlite expansion furnace, it is a kind of white granular material with a honeycomb structure inside which is made by preheating and instantaneous high temperature roasting. The principle is as follows: the perlite ore is crushed to form a certain size of ore. Thermal calcination, rapid heating (above 1000 °C), water vaporization in ore, expansion in softened vitreous ore containing sand, forming a porous structure, volume expansion 10-30 times of non-metallic mineral products.

Light weight , Porous , Insulation , Incombustible , Sound absorption , Water resistance , Non-toxic , Anti-corrosion

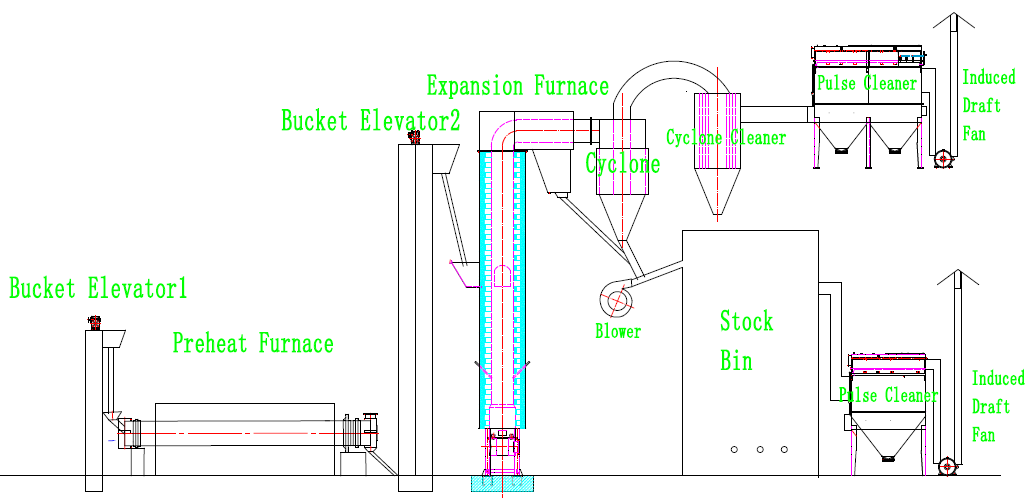

The whole perlite expansion furnace system include equipment: bucket elevator, indirect preheating furnace (include burner), main bucket elevator and chute, expansion furnace and burners, stainless steel water cooling chamber and final products collector, cyclone dust collector, multi tube cyclone dust collector, finished products silo(stock bin), pulse bag dust collector and so on.

The ore particles are controlled by the force in the direction of the furnace chamber. The force of the ore can be summarized into two types: one is gravity, which guides the ore to move downwards freely. The second is buoyancy, contrary to the direction of gravity, slowing the speed of free fall of the particles.

At the beginning of the ore entering the furnace chamber, the buoyancy of the updraft is less than its own gravity, and it moves downwards itself: when it is heated above 850 °C during its falling motion, it begins to expand, the volume increases, and the buoyancy increases. When the buoyancy exceeds its own gravity, the expanded ore particles begin to rise with the hot gas flow and continue to be heated and expanded.

After the expanded particles reach the top of the kiln with the hot air, they are guided by the drafting fan to introduce the water-cooled horizontal separator and the cyclone separator to complete the product separation. The separated finished products (expanded particles) are sent to the final products silo by the blower, and are weighed, packaged and shipped.